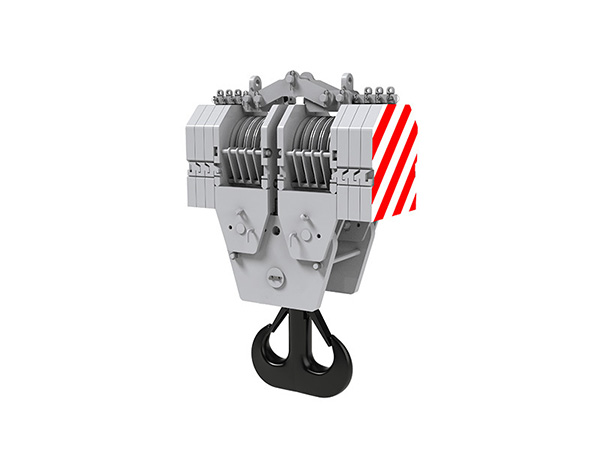

Universal Hook Block

Applied in the lifting mechanisms of cranes. Production lead time is 20 days.

Tonnage:3.2t,500t,5t,10t,16t,20t,32t,50t,75t,100t,125t,160t,200t,250t,320t,400t

Hook Material:DG20,DG20Mn,35CrMo,34Cr2Ni2Mo,30Cr2Ni2Mo

Pulley Material:Q355B Pulley Process Hot Rolled

Bearing Brands:SKF、FAG、NSK,HRB, WGYS, LYC,Other Brands

·Overview

Introduction to Crane Hook Blocks

Crane hook blocks, also known as lifting hook assemblies or crane hook groups, are essential components in various industries such as industrial cranes, engineering machinery, mining, metallurgy, chemical, aerospace, military, and marine sectors. These components are pivotal in lifting operations, offering robust functionality and reliability in diverse environments.

·Structure and Components

A typical crane hook block consists of several key elements designed to ensure safe and efficient lifting:

1. Hook Assembly: The main lifting hook is forged or fabricated from high-strength alloy steel to withstand heavy loads. It is designed with safety latches or locks to prevent accidental release of the load. 2. Sheaves and Bearings: The hook block incorporates multiple sheaves (pulleys) mounted on bearings. Sheaves are carefully engineered to minimize friction and distribute loads evenly, enhancing operational efficiency.

3. Wire Rope or Chain: Depending on the application, crane hook blocks are equipped with wire ropes or chains that pass through the sheaves. These components are selected based on load capacity and environmental conditions.

4. Frame and Housing: The frame of the hook block provides structural support and houses the sheaves and bearings. It is constructed from robust materials to endure rigorous usage.

·Applications

Crane hook blocks play a crucial role in various industries:

- **Industrial Cranes**: Used for lifting and moving heavy loads in manufacturing facilities, warehouses, and construction sites.- Engineering Machinery: Essential for lifting operations in construction equipment such as excavators, loaders, and material handlers.- Mining and Metallurgy: Deployed in mining operations for extracting minerals and in metallurgical processes for handling molten metals.- Chemical Industry: Utilized in chemical plants for lifting and moving equipment and materials safely.- Aerospace: Critical in aerospace applications for assembly, maintenance, and repair of aircraft and spacecraft.- Military: Used in defense applications for logistics, vehicle maintenance, and deployment of equipment in field operations.- Marine: Essential on ships and offshore platforms for lifting cargo, equipment, and performing maintenance tasks.

Safety and Standards

Due to the critical nature of lifting operations, crane hook blocks adhere to stringent safety standards and regulations. They undergo rigorous testing and inspection to ensure reliability and compliance with industry norms.

In summary, crane hook blocks are indispensable components across a spectrum of industries, facilitating safe and efficient lifting operations. Their robust design, coupled with adherence to safety standards, makes them vital assets in industrial settings worldwide. As technology advances, these components continue to evolve, enhancing their performance and versatility in meeting diverse lifting challenges.

A crane hook serves as an essential piece for attaching loads to a crane or hoist. Its purpose is to securely bear and lift target weights while facilitating effortless attachment and detachment,easy assembling and disassembling, andfast wire rope reeving.

Single and Double Crane Hooks:Crane hooks can be classified into single and double types based on their configurations. Single crane hooks are suitable for machinery handling loads of up to 75 tons. They are easy to use in different variants. In contrast, double crane hooks share a similar design but offer increased working load capacities, making them dependable for handling heavier loads exceeding 75 tons.

Closed and Semi-Closed Crane Hooks:When considering ingress protection grade, you have the option to choose between closed and semi-closed crane lifting hooks. While closed crane hooks may be more challenging to operate and consume more time, they offer the highest level of safety measures. Semi-closed crane hooks strike a balance by providing enhanced security compared to standard lifting hooks, all while being relatively easier to attach, detach, and maintain compared to closed hooks.

Forged and Laminated Crane Hooks:Crane hooks can be categorized based on their manufacturing methods into forged and laminated types. Forged crane hooks are crafted from a single piece of high-quality, low-carbon steel and are slowly cooled to ensure optimal stress resistance. In contrast, laminated crane hooks are composed of multiple steel plates riveted together, offering increased safety and improved performance, particularly under high-temperature conditions.

Typically made of high-strength steel or alloy, Purui's crane hooks underwent industry-proven processes, including blanking, heating, forging, normalizing, polishing, machining, painting, hardness testing, and ultrasonic testing. This meticulous series of steps ensures that the hooks can confidently bear the specified weight for lifting tasks. Hooks come in diverse shapes and sizes, tailored to serve different applications and working loads. Safe to say the selected crane hook parameters significantly influence the efficiency and safety of lifting operations.

| Tonnage | Dimensions in mm | Installing wire rope | |||||||||||

| A | B | AND | G | D | D1 | L | L1 | L2 | d | c | Diameter (mm) | Number of branches | |

| 3.2t | 637 | 338 | 245 | 130 | 250 | / | 222 | / | / | 65 | 50 | 11~14 | 4 |

| 5t | 846 | 382 | 320 | 236 | 350 | / | 184 | / | / | 85 | 650 | 11~14 | 4 |

| 10t | 1110 | 370 | 420 | 240 | 400 | 250 | 93 | / | / | 120 | 90 | 11~14 | 6 |

| 16t | 1277 | 512 | 440 | 285 | 500 | 300 | 179 | / | / | 150 | 115 | 14~20 | 6 |

| 20t | 1440 | 516 | 520 | 335 | 500 | / | 134 | 94 | / | 170 | 130 | 16~20 | 8 |

| 32t | 1730 | 596 | 610 | 420 | 610 | / | 154 | 108 | / | 210 | 160 | 18~22 | 8 |

| 50t | 2085 | 724 | 720 | 510 | 710 | 610 | 161 | 108 | / | 270 | 205 | 20~22 | 10 |

| 75t | 2335 | 970 | 930 | 600 | 800 | 500 | 185 | 135 | / | 320 | 250 | 26~32 | 10 |

| 100t | 3130 | 1360 | 1100 | 955 | 1000 | 800 | 131 | 200 | 350 | 335 | 270 | 28~34 | 12 |

| 200t | 3548 | 1707 | 1090 | 1318 | 1000 | 900 | 173 | 280 | / | 295 | / | 30~38 | 16 |

| 320t | 4005 | 2004 | 1350 | 1235 | 1120 | 1000 | 160 | 316 | / | 370 | / | 40~46 | 24 |

| 400t | 4315 | 2338 | 1450 | 1270 | 1120 | 1000 | 160 | 316 | / | 420 | / | 40~46 | 24 |

·Production Map

About Weihua

Weihua Heavy Machinery Co., Ltd. was founded in 1988. It is a large-scale equipment manufacturing enterprise mainly engaged in the development of bridge and gantry cranes, port machinery, electric hoists, reducers, bulk material conveying equipment and other products.

Weihua has won more than 500 honorary titles such as "National Technology Innovation Demonstration Enterprise", "National Torch Program Key High-tech Enterprise", "National Certified Enterprise Technology Center", "National Quality Benchmark", "National Green Factory", and "National Industrial Design Center".

Weihua has 10 series and more than 200 categories of crane production and manufacturing qualifications. The leading products are widely used in machinery, metallurgy, mining, electricity, railways, ports, petroleum, chemical and other industries, serving national key projects such as West-East Gas Transmission, South-to-North Water Diversion, Olympic Projects, Hangzhou Bay Cross-sea Bridge, and thousands of large enterprises such as China Coal, China Shenhua, Sinopec, China Petroleum, Baowu Steel, etc., and are exported to more than 170 countries and regions such as Thailand, Malaysia, and Australia.

Weihua has 33 national and provincial R&D platforms, and a scientific research team of more than 1,200 people led by Zhang Tiegang and Ma Yushan, academicians of the Chinese Academy of Engineering. It has successively undertaken 7 major national projects. The independently developed electrical anti-sway control technology is internationally leading. The 400-meter ultra-high winch has set a world record for the maximum lifting height. The AICrane intelligent control system has created a real crane robot. The new Chinese-style crane has redefined the concept of lifting and promoted the continuous iteration and update of China's lifting technology! Create Weihua international brand and promote the Chinese national industry. Henan Weihua is committed to becoming a global leading material handling equipment manufacturer and system solution provider, and contributing a world-class brand to the high-end equipment manufacturing industry.

|

|

|

|

|

|

|

|

Inquiry

Please leave us your requirements, we will contact you soon.